The Bourbon and Tobacco Tour has been postponed to July 24-25, 2021.

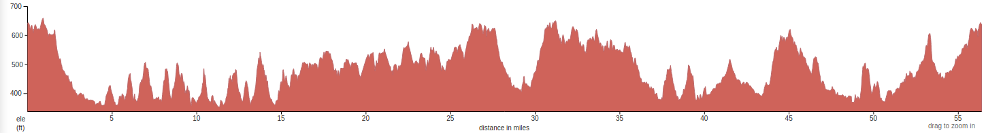

Good pavement, nice gravel, light vehicle traffic, courteous drivers, and the hills of western Kentucky in the springtime – what’s not to like? Well, your legs might complain about some of the gradients, but the descents make it all worthwhile. And the riding companions – unparalleled.

A few updates for the COVID mess:

Rather than meeting at my house for dinner after the Saturday ride, we’ll just pick up dinner in Cadiz and meet at the park on the west side of town to eat and tell biking lies. My wife will be much happier with this, and there’s plenty of parking and tables for us. Because I don’t know what will transpire between now and the ride, please bring a mask and put it in your jersey pocket.

There are plenty of places to pick up some food – pizza at Casey’s, mexican at El Bracera, Sonic, Wendy’s, Taco Bell, KFC, Triplets, Cracker Barrel, and Subway. I’d rather have everyone at my house for a cookout, but I’m trying to make some adjustments that will work for everyone. I appreciate your understanding.

Friday dinner, July 23:

For those folks coming into town on Friday, we’ll meet at Triplett’s BBQ in Cadiz around 6pm for dinner. The restaurant is on US68/KY80 just west of I-24 at exit 65.

Saturday, July 24:

We will meet at 9:30am at the LBL Golden Pond Visitor Center on the Woodlands Trace Road, at the intersection of US-68/KY-80. There is plenty of parking at the visitor center. I will have some repair/adjustment tools, grease, chain lube, floor pump, work stand, and some spare tubes and patches. Hopefully no major repairs will be needed before, during, or after the ride but we’ll be prepared for the usual (and some of the unexpected). We’ll roll out from the parking area around 10am.

We will have a SAG driver again this year. It was a real luxury to have Greg volunteer his time and gas to follow us around in LBL, and he’s planning to join us again.

There is no cost for these rides, but if you wanted to kick in a few dollars for our SAG driver’s gas or a bite to eat for him I’m sure he would appreciate it.

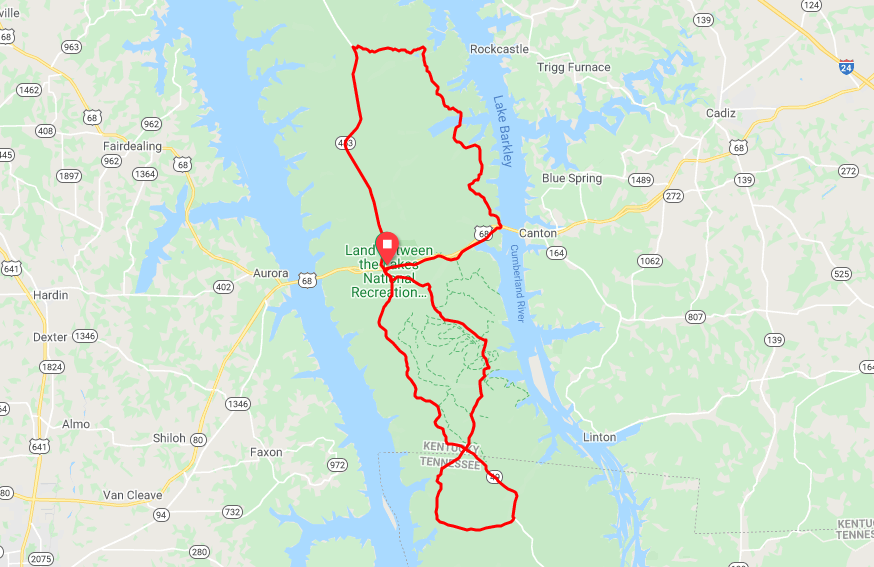

The route:

The route is the same as the 2020 ride, and is entirely within the LBL. This loop starts and ends at the Golden Pond Visitor Center in LBL, and is about 56 miles, all paved, with about 3500 feet of climbing. There are a small number of actual turns in this route, so hopefully there won’t be any issues with navigation or getting lost. I will give my cell number to riders, should assistance be needed during the ride. Cell coverage isn’t always the best in LBL, so bear that in mind. This is an unsupported ride, but we will do our best to help everyone finish up safely.

Click to Download Cue Sheet for the full route

Click to Download Cue Sheet for the partial route

Other cool stuff to do:

If you want to come in a day early, or stay over for a day or two, you could follow the Kentucky Bourbon Trail. If you like bourbon and want to sample the offerings by several distilleries, this is a great way to do it. Check out where the distilleries are located and plan your route.

You can drive north on the Trace Road, and drive through the Elk and Bison Sanctuary. There’s a small fee at the entrance to the sanctuary, and it’s well worth it. I’ve been there more than once and it’s a unique opportunity to see herds of bison and elk moving around the area. You do have to be in a vehicle – a bicycle vs a 2000 pound bison – no thanks.

There is a trap range close to the Lake Barkley Lodge, so if folks are interested we can shoot some clay targets. No prizes, just bragging rights. I have shotguns, ammunition, and clay targets – so all you’ll need is hearing and eye protection. If you’ve not done this before, it’s challenging and fun. If you’re new to this, I’ll be happy to help you shoot safely.

Post-ride cookout:

See the COVID notes above for Saturday dinner plans.

Sunday, July 25 – ride the trails:

If folks are interested, we’ll take some fatter-tired bikes out for some trail riding on Sunday. There’s a lot to choose from, the map links below will give you an idea of the variety available to us. A good choice is the Hardwoods Trail, from east to west all the way to Kentucky Lake. Mostly crushed limestone and a lot of fun. I would rate this trail as easy/moderate. Bikes with road tires won’t be the best choice for this – wider tires are the best way to go.

A local friend and riding buddy will lead the gravel ride on Sunday, he knows the gravel routes in LBL much better than I do.

At the north end of the LBL, there is a good singletrack loop named the Canal Loop. I would rate this loop as moderate/difficult.

There is a fairly new option, the trails in Livingston County, to the north of LBL. I’ve ridden there a few times and it’s a lot of fun. These trails are rated intermediate/difficult, so bring your “A” game. Be advised, you will want some tread on your tires for these trails.

We’ll figure out when and where to meet during the cookout and I’ll update the information here.

LBL Maps – click the Trails tab.

There are 500 miles of trails and 200 miles of roads in LBL. It is great to have this area so close to home. Not all of the trails are available for bicycling, so check the website while you scout a potential route.

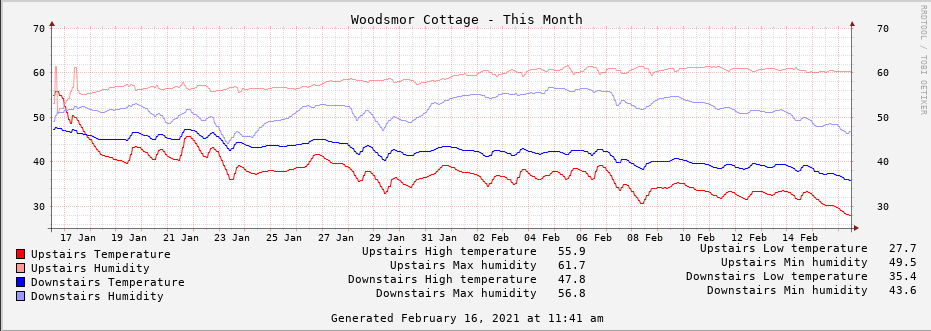

Temperatures to expect:

The average high temperature in July is in the mid-to-upper 80s, and a low average in the upper 60s, so warm but still pretty good riding weather.

Lodging:

Here are some options for lodging and some suggestions for restaurants in the area.

Kenlake State Resort Park Reservations – this is a good choice if you want to ride to the start

Lake Barkley Lodge reservations – there is now a bike path paralleling us-68/KY-80 to the west so it’s a good ride to the start

Both are reasonably priced and are just a few minutes from our starting place. Kenlake and Lake Barkley both have restaurants too. For those folks arriving on Friday, we’ll meet for dinner.

Red Roof Inn – Cadiz – this is about a 15-20 minute drive to the start

Quality Inn – Cadiz – this is about a 15-20 minute drive to the start

Both of these hotels are at I-24 exit 65, and are within walking distance of Triplets. Driving time to the start point is 20-30 minutes.

Bike Shop:

Bikes and Moore in Hopkinsville is a great shop that I’m happy to call “home”. I couldn’t find a complaint if I tried. Good folks and they’ll be happy to help you out, should you need more than a tweak or two. They have knowledgeable mechanics and a good parts inventory too if it comes to that.

Questions:

Contact me if you have any questions, I’ll do my best to help.

Please watch your speed while driving in LBL, it’s federal land, so speeding tickets are expensive – paraphrasing Agent K – “the rangers do not have a sense of humor they’re aware of.”